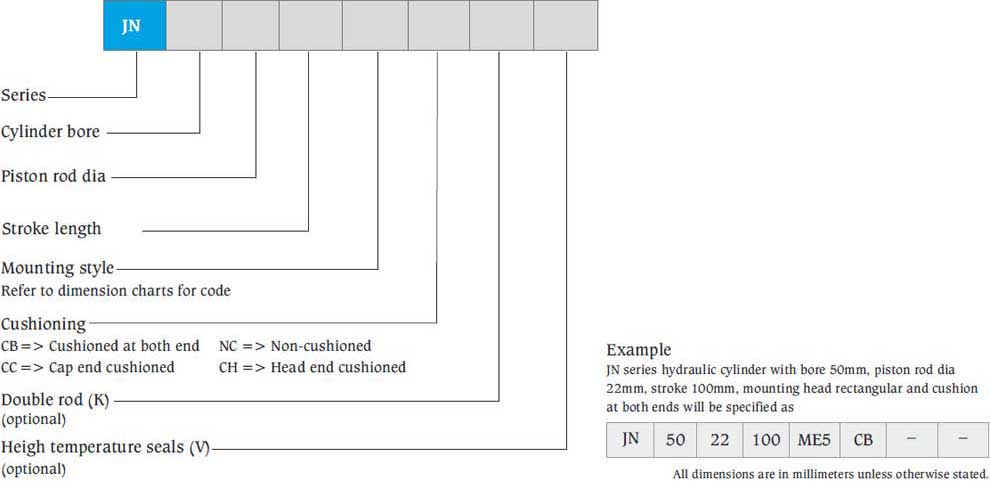

JN Series

| Piston rods | Cushioning |

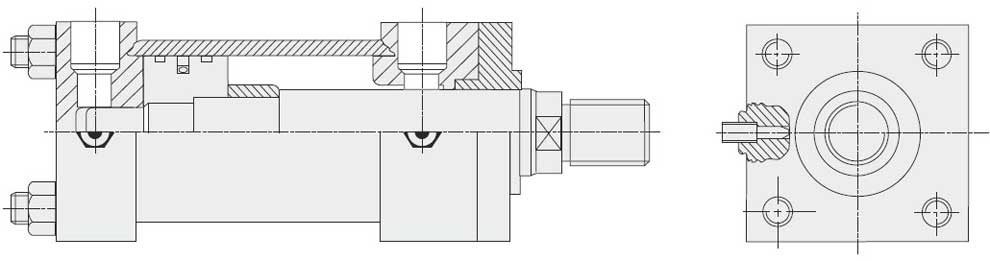

Made from medium carbon Steel. Precision ground, hard chrome- plated and polished to ensure smooth, dent & rust resistant surface for best sealing and long life. |

Self-aligning cushioning bush ensures alignment of the rod movement inside the cushioning chamber, providing accurate damping action at the end of stroke. |

| Barrel | Cushioning adjustment |

Made from cold drawn seamless Steel tubes. Honed to 0.4 micron and higher surface finish to minimize internal friction and longer seal life and performance. |

For fine adjustment of cushioning movement. |

| Cover plates | Piston seal |

Fine machined from Steel and constructed with a sturdy design to withstand high pressure loads. |

Provided with low friction single piston seal design for no stick-slip effect in rotated two wear strips. This design provides smooth operation, long bearing life and high load carrying capacity. |

| Piston rod gland | Rod seal |

Made from Turcite T47 material. Non-metallic wear rings are used in the cylinder head for precisely guiding the piston rod of the working cylinder and absorbing lateral forces which occur. At the same time, metallic contact between the sliding parts of the cylinder, e.g. piston rod and cylinder head must be prevented. Nonmetallic wear rings offer major benefits compared to metallic guides. |

Polyurethane U-cup seal is used which has double lip design for good sealing effect & maximum flexibility. |

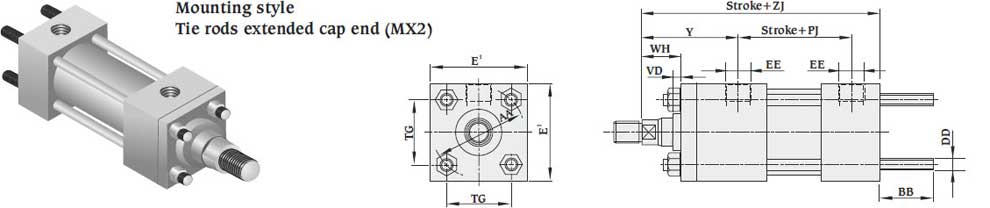

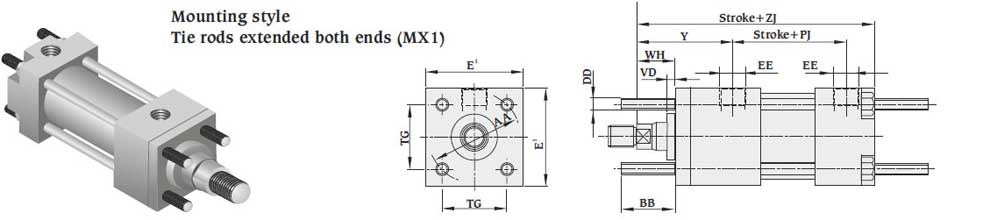

| Tie rods | Wiper seal |

Made from high tensile Steel rods tightened with hexagonal nuts for easy maintenance. |

The wiper is a double working nitrile wiper seal. The wiper lips are designed to wipe off dust and provide light sealing. It has advantage of radial tension to wipe off particles, dust and water. |

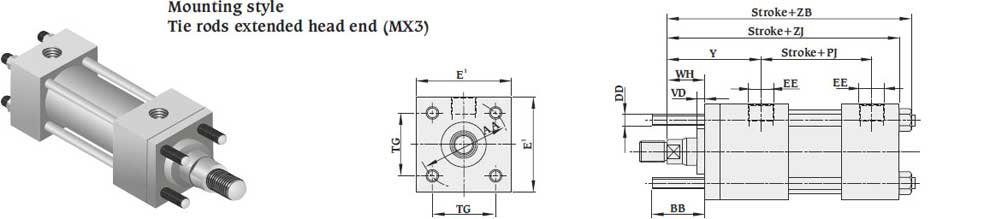

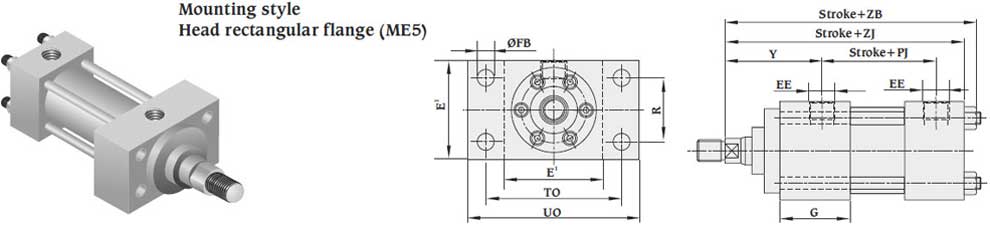

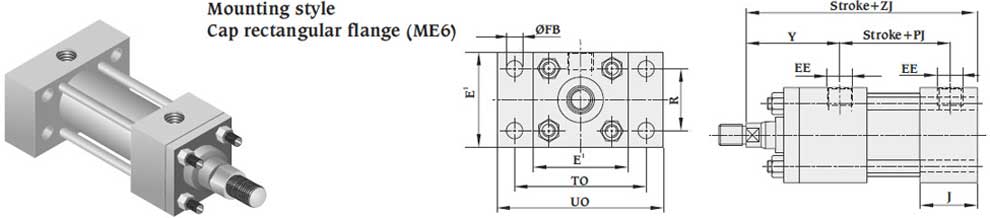

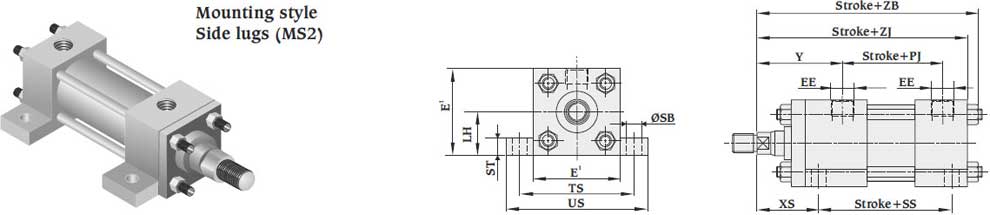

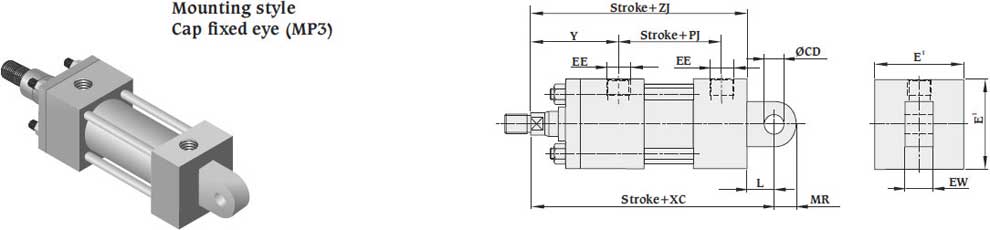

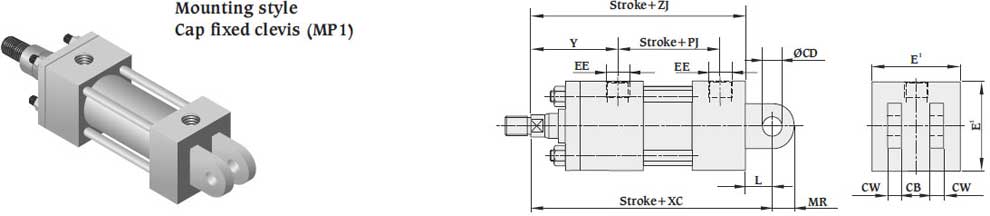

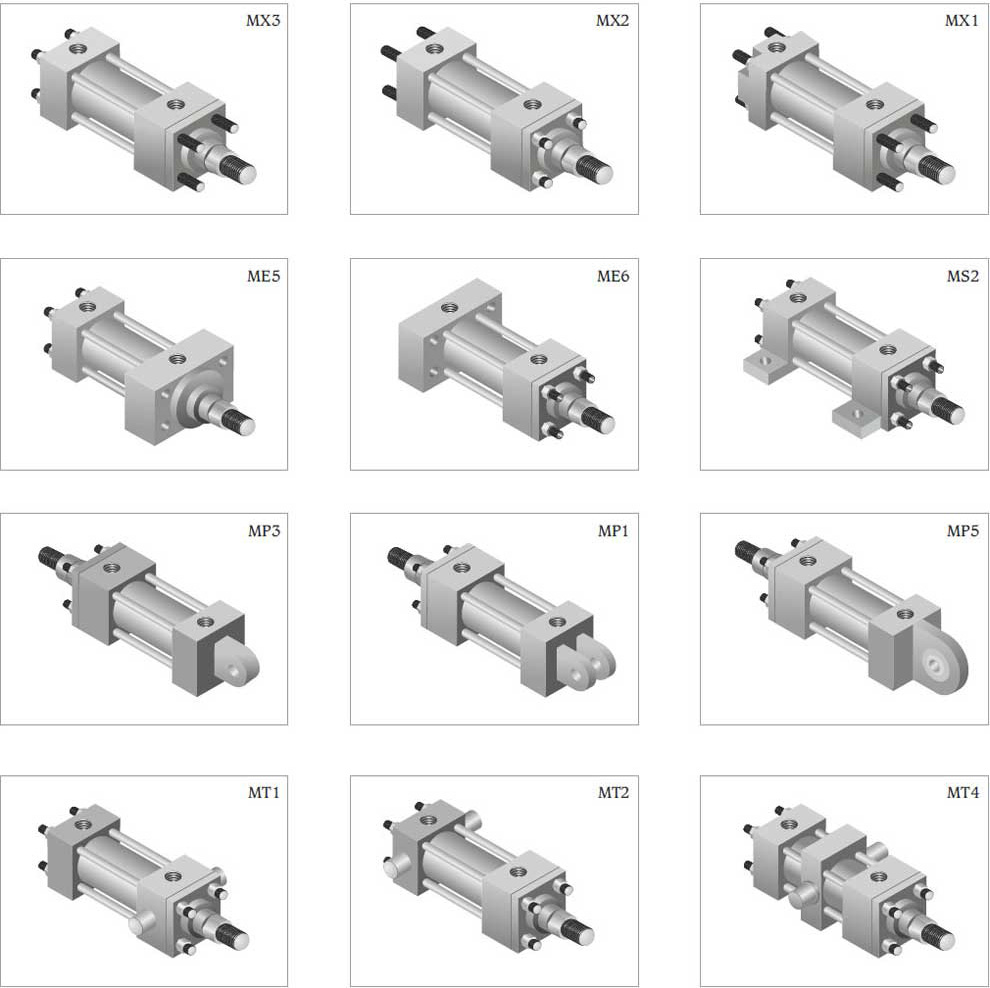

• 12 Standard mounting styles

• Provision for smaller as well as bigger rod diameter for each bore size

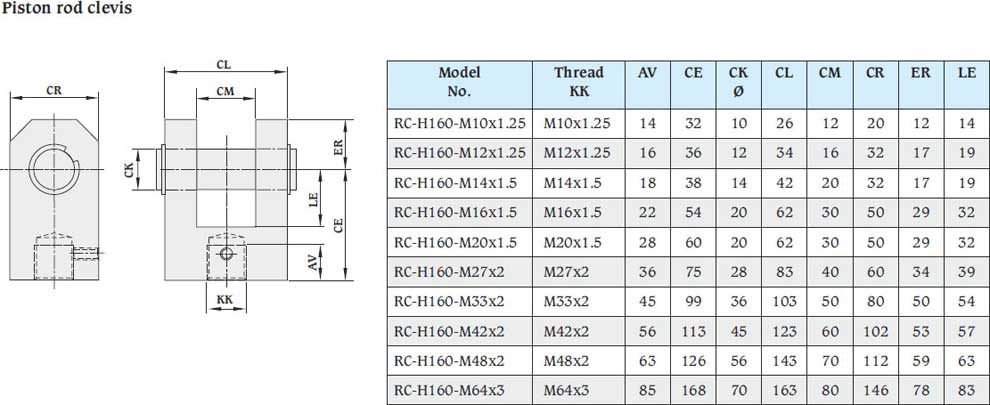

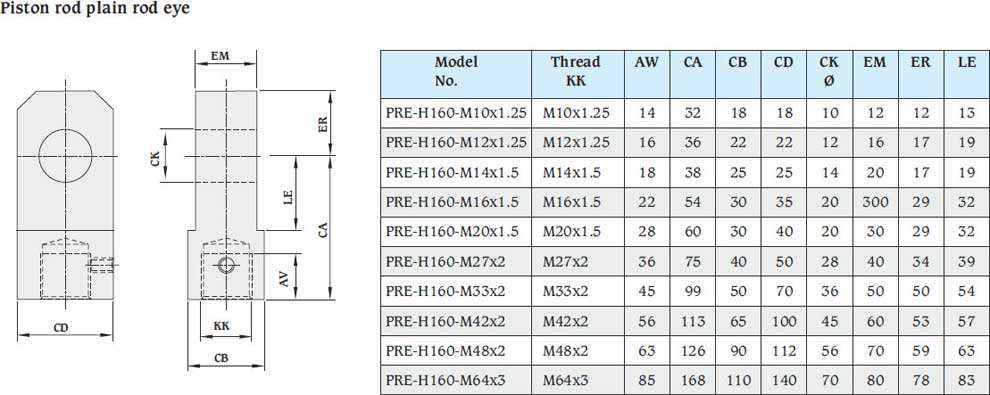

• Wide range of mounting accessories

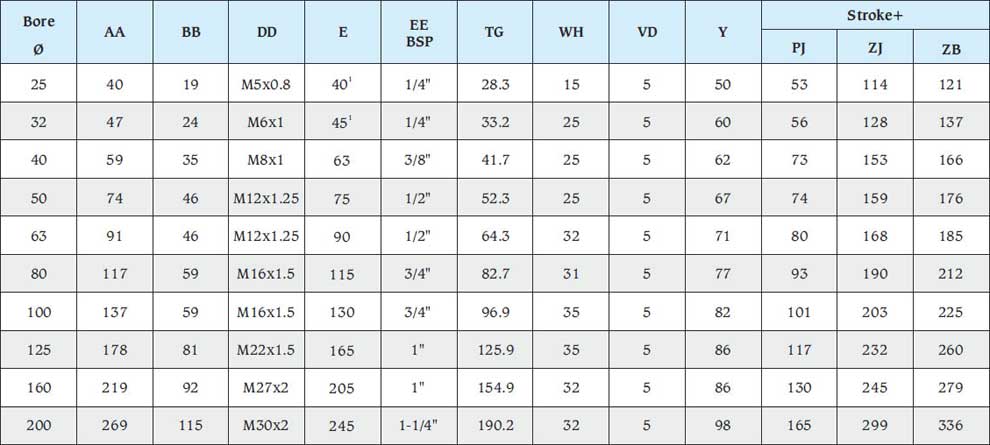

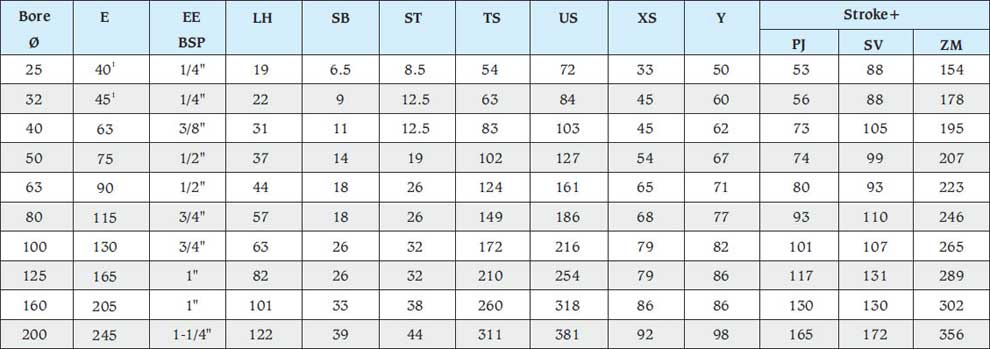

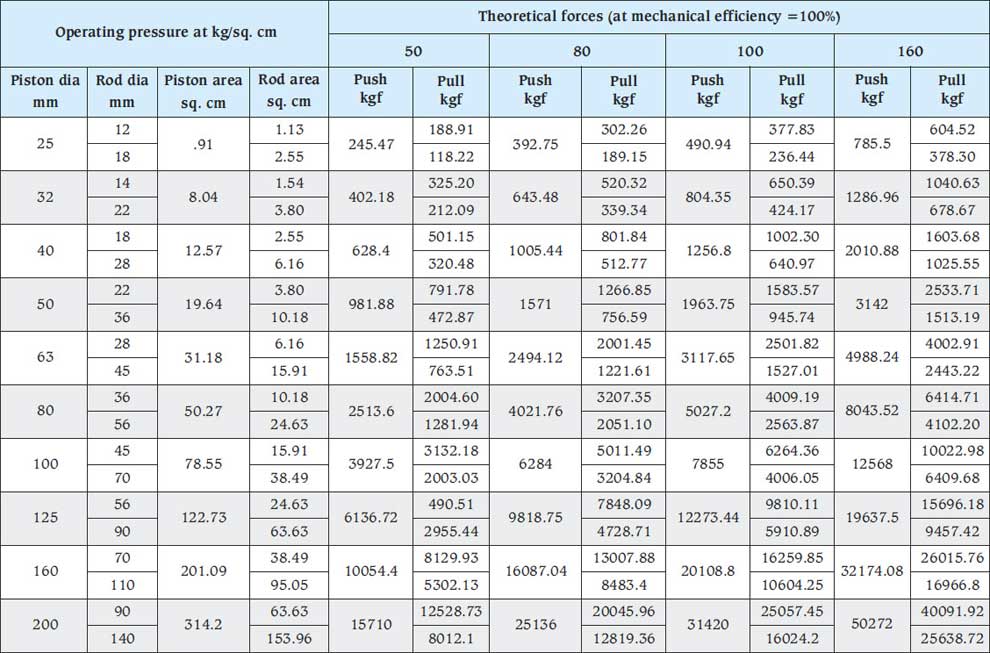

• Bore sizes - 25mm to 200mm

• Available in any practical stroke length

• Maximum working pressure 160 bar

• Piston rods - 12mm to 140mm

• Single and double rod design

• Cushioning available from 63mm bore onwards

• Cushions available at either ends

• Temperature range : -

-20 C to +80 C (standard)

-20 C to +150 C (optional)

• Seal types to suit a wide variety of applications

• Standard fluid : Mineral oil, DIN 51524 (HL, HLP)

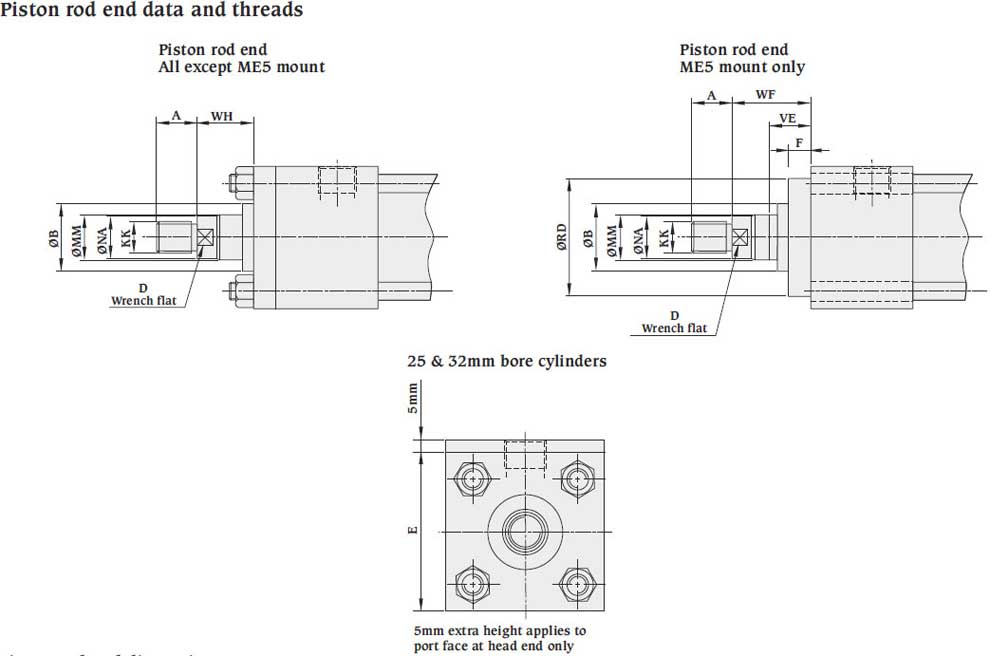

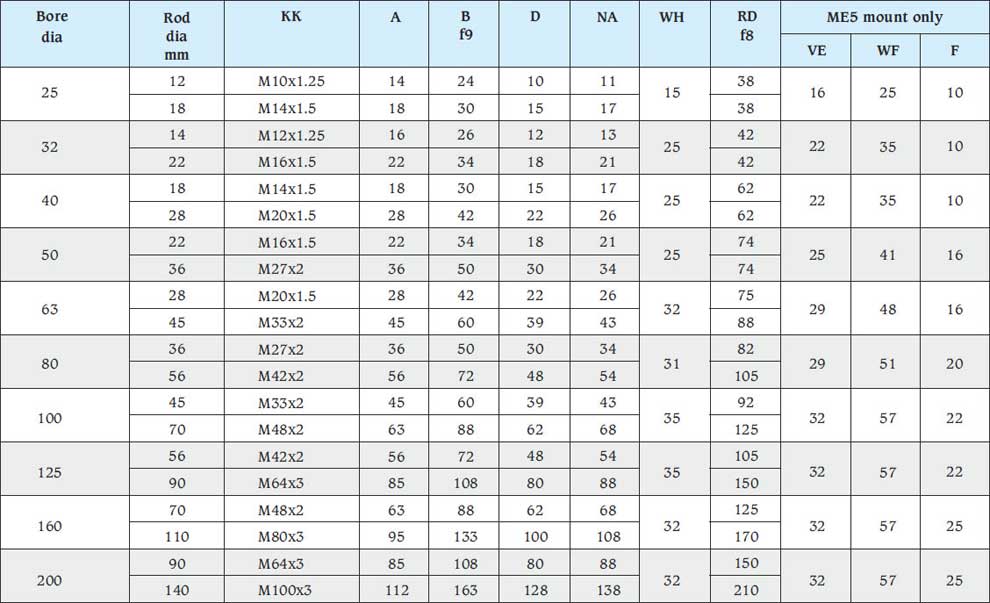

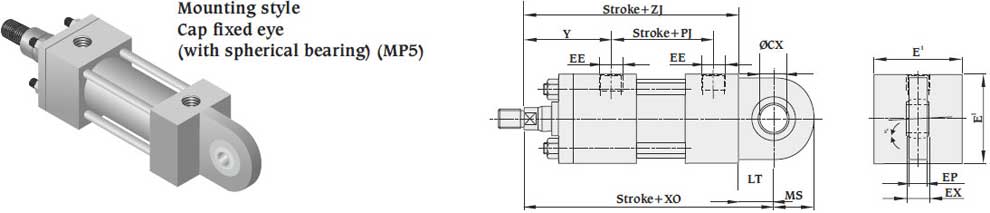

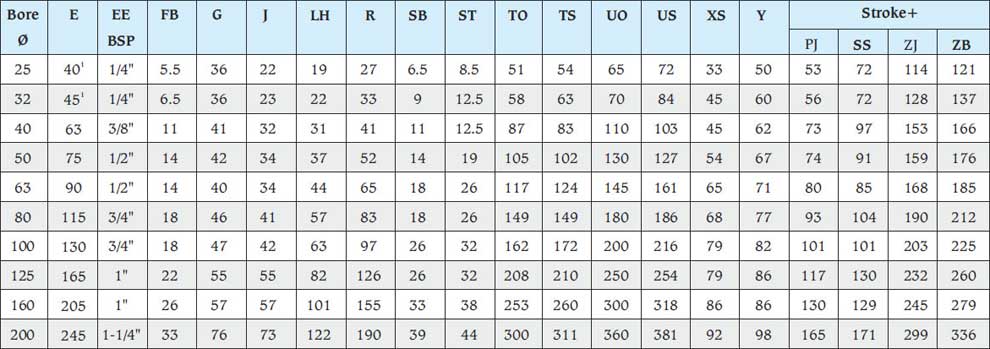

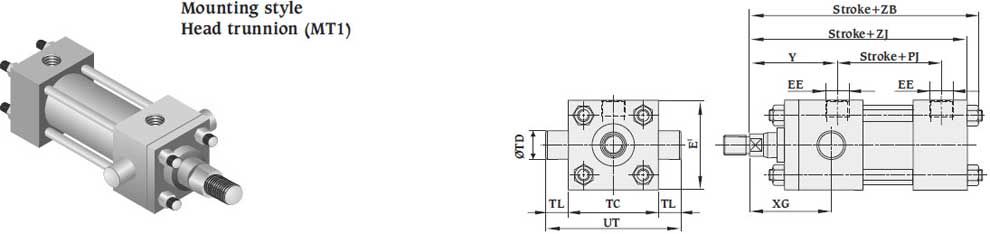

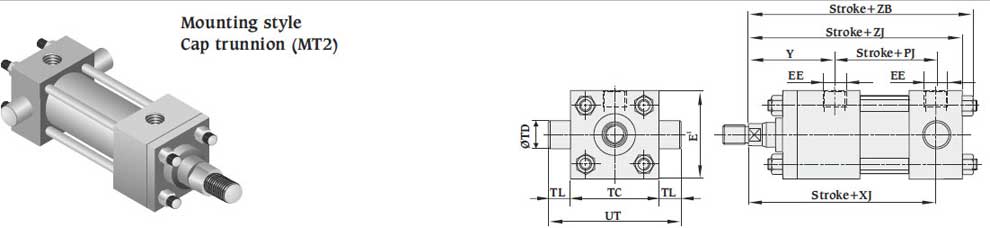

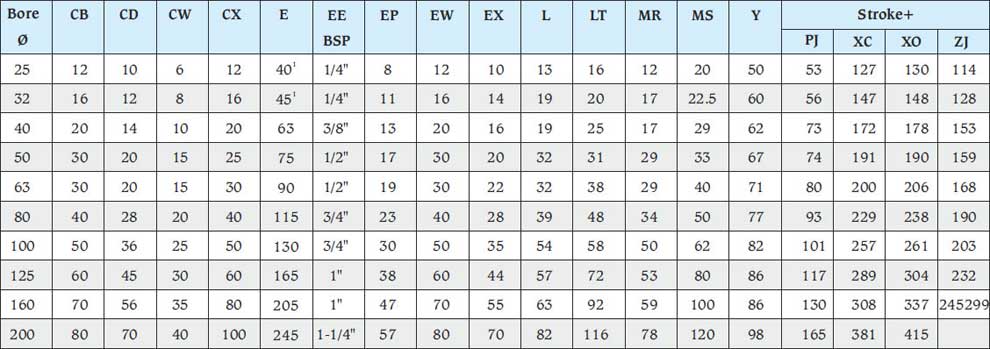

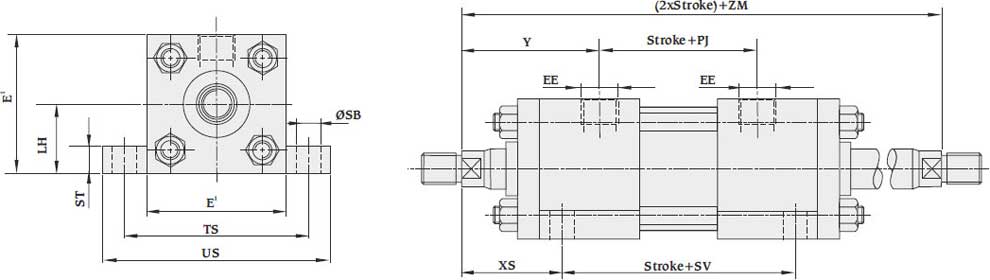

All dimensions are in millimeters unless otherwise stated.

You can find more products, Please go through our other websites: www.duttacontrol.com , www.suryapneutech.com